Ford, Heinz Working To Make Car Parts From Tomatoes

The last thing you want when you buy a car is a lemon. But the folks at Ford and Heinz think you may someday want a tomato; or at least a car made with tomato-based parts.

The last thing you want when you buy a car is a lemon. But the folks at Ford and Heinz think you may someday want a tomato; or at least a car made with tomato-based parts.

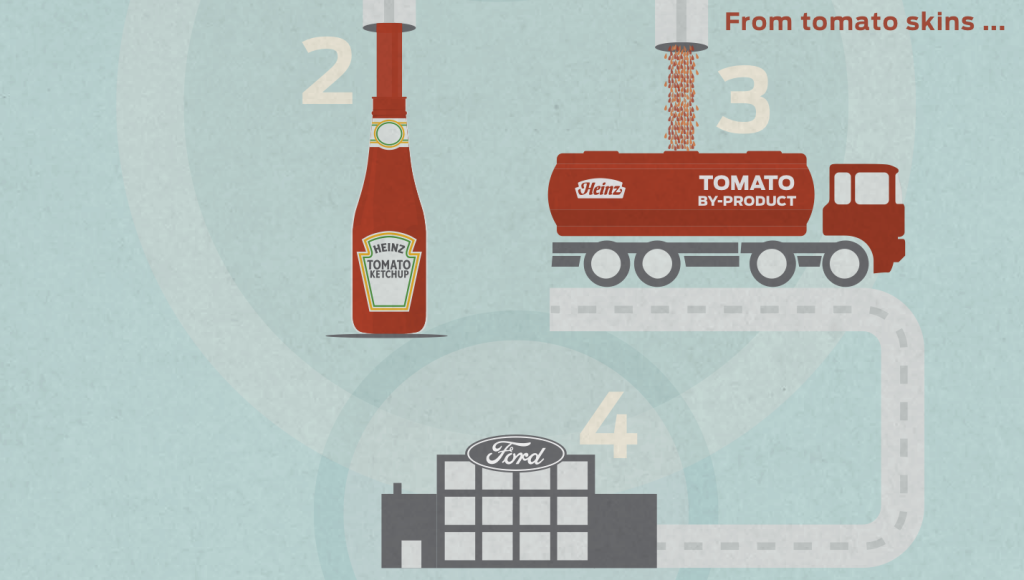

Unlikely collaborators Ford Motor Company and H.J. Heinz Company announced Tuesday they are exploring the use of tomato fibers in developing sustainable, composite materials for vehicle manufacturing, while also reducing the overall environmental impact of automobiles.

Fibers used to create the materials come from the more than two million tons of tomato peels, stems and seeds leftover from Heinz’s annual production of ketchup.

Fibers used to create the materials come from the more than two million tons of tomato peels, stems and seeds leftover from Heinz’s annual production of ketchup.

The latest innovations being explored include using dried tomato skins in wiring brackets and in the storage bins used to hold coins and other small objects.

“Although we are in the very early stages of research, and many questions remain, we are excited about the possibilities this could produce for both Heinz and Ford, and the advancement of sustainable 100% plant-based plastics,” Vidhu Nagpal, associate director of packaging for Heinz, says in a statement.

Ford began collaborations with Heinz, The Coca-Cola Company, Nike and Procter & Gamble, more than two years ago in an attempt to develop 100% plant-based plastic for use in vehicle fabric and packaging.

Other Ford bio-based products include the use of coconut-based composite materials, recycled cotton used in carpeting and seat fabric, and soy foam seat cushions and head restraints.

No word yet on whether vehicles with the new components will smell like the inside of a tomato, but we’re hoping that won’t be the case.

You Say Tomato; We Say Tom-Auto: Ford and Heinz Collaborate On Sustainable Materials For Vehicles [Ford Motor Company]

Want more consumer news? Visit our parent organization, Consumer Reports, for the latest on scams, recalls, and other consumer issues.